Single Former Holder Part Manufacturer – L96mm L10mm aluminum casting with electroplating – DEMY

Single Former Holder Part Manufacturer – L96mm L10mm aluminum casting with electroplating – DEMY Detail:

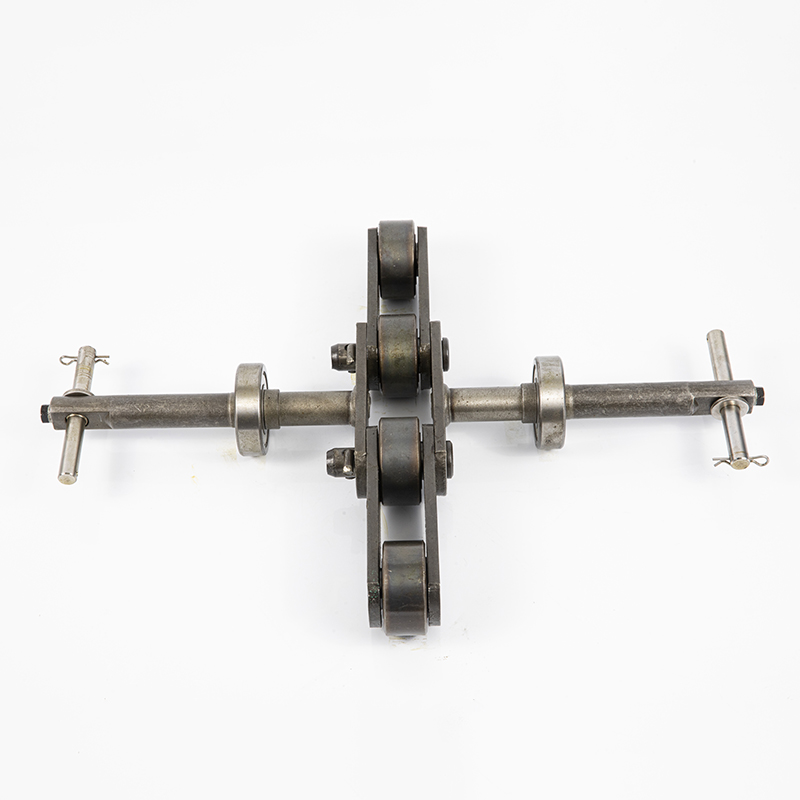

A former holder assembly for holding former holders used in the latex dipping industry for the production of latex dipped products such as latex gloves comprising: At least one essentially U-shaped bracket having one concentric hole through each of the two upright ends so that a bolt or a pivotal rod can pass through the holes and being securely fastened to the bracket.

Two L-shaped arms comprising of an upright portion and a base portion serving as part of the former holder assembly. The upper end of the upright portion of the L-shaped arms is fitted securely on to the pivotal rod of the U-shaped bracket wherein the free end of the base portion is designed to hold at least one former holder.

The double indexing cap former holder includes a roller disc, a first indexing cap, a second indexing cap, an elongated shaft, a former holder spring and a housing arm structure. The roller disc of the double indexing cap former holder is coupled with the first indexing cap. The second indexing cap is attached to the first indexing cap and has at least one flat surface on the side. In addition, the top edges of the second indexing cap extend out for properly orienting the glove formers in the glove manufacturing process. The elongated shaft is attached to a lock plate at one end, which engages with the roller disc. The lock plate of the elongated shaft is coupled with the roller disc using an EPDM (ethylene propylene diene monomer rubber) or silicon sheet, which is placed in between the lock plate and the roller disc. A second end of the elongated shaft is attached to one end of the housing arm structure. The housing arm structure connecting the elongated shaft and the glove manufacturing line is an L arm double line. A number of bearings are provided between the ends of the housing arm structure and the elongated shaft for enabling easy movement of the elongated shaft along the glove production line. The former holder spring is positioned around the elongated shaft and a spring cap stops the spring at the top end of the elongated shaft near the housing arm structure. The L arm double line or the housing arm structure connecting the elongated shaft and the glove manufacturing line enable the former holder attached to the end of the double indexing cap former holder to rotate and stable at two orientations that helps to reduce the bypassing of gloves during the glove stripping and layering process.

Company Information

Exhibition

Certificate

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Single Former Holder Part Manufacturer – L96mm L10mm aluminum casting with electroplating – DEMY, The product will supply to all over the world, such as: Denver, Portland, Nepal, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.