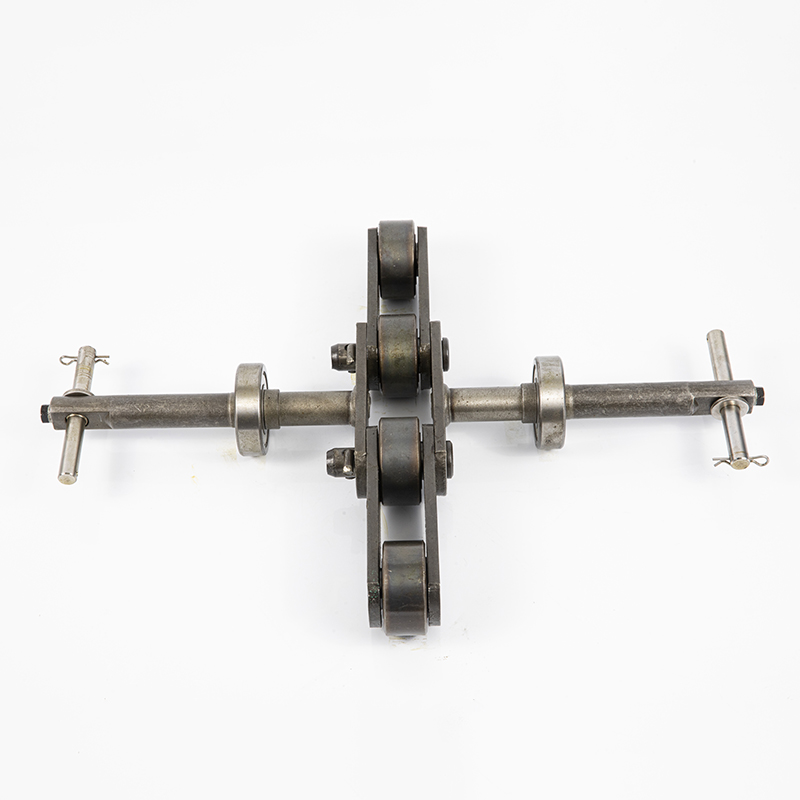

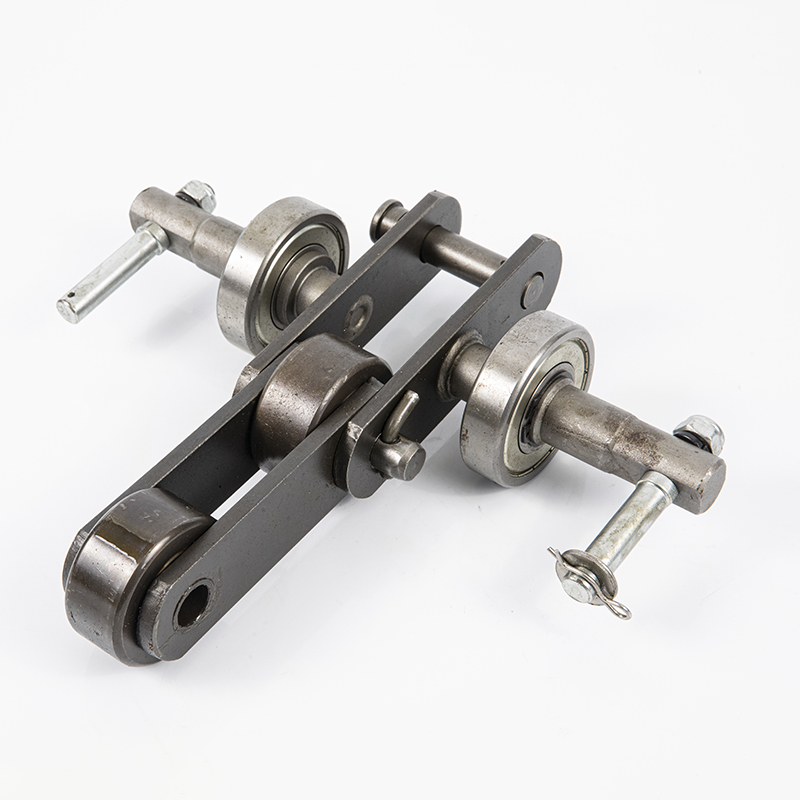

Glove Roller Chain Part Factory – 1602 infra red burner for production line – DEMY

Glove Roller Chain Part Factory – 1602 infra red burner for production line – DEMY Detail:

The products are mainly used in curing the coating, pretreatment drying, food baking lines, textile printing and dyeing pre-bake, baking carpet glue, condoms and medical disposable gloves and other manufacturing lines.

Boutique series gas infrared burner porous ceramic plate as the combustion medium. The use of advanced science and technology design made. When the combustion gas sufficiently premixed with the air, so that the combustion gas, thereby reducing pollution; combustion infrared radiation it has a strong penetrating power, the heat can uniformly penetrate into the core to be heated to ensure uniform heating effect, improve heating quality and drying efficiency, environmentally friendly energy-efficient products.

Work characteristics:

Safety: The 2.8 kPa low pressure natural ejector way premixed, more secure and reliable.

Efficient: Imported ceramic plate heat storage capacity, wide adjustment range, good radiation effects; its surface temperature may be in the range of 475 to 950 degrees Celsius adjusted to better carry out the coating operations. Energy Saving: 1.63KW monolithic ceramic plate heating power, 0.12kg / hr monolithic ceramic plate ultra liquefied gas consumption.

Environmental protection: the entire system COX, NOx emissions below international standards related industries (in the standard system configuration and use of environment).

Wide range of applications: the option of using natural gas, liquefied petroleum gas, artificial gas and other gas. Accurate control: drive, actuators and butterfly valves, furnace temperature throughout the system, PLC or OPTO22 central control module for precise control of the combustion.

Heat intensity (power density): 135 kilowatts / square meter

Applicable gas pressure: 2.8 kPa (premixed natural state), or 1.0 to 1.5 kPa (artificial premixed state)

Inlet pressure during artificial premix: 2.5 to 3.0 kPa

Pipe diameter: depending on the specific circumstances

Gas adjustment: flow regulator (actuator plus valve or loop tube) or pressure regulator (regulator)

Ignition: electronic pulse ignition, or ceramic heater ignited

Control: temperature control table thermocouple + + simple electronic push-button control; or PLC control.

Company Information

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for Glove Roller Chain Part Factory – 1602 infra red burner for production line – DEMY, The product will supply to all over the world, such as: Slovakia, India, Burundi, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!