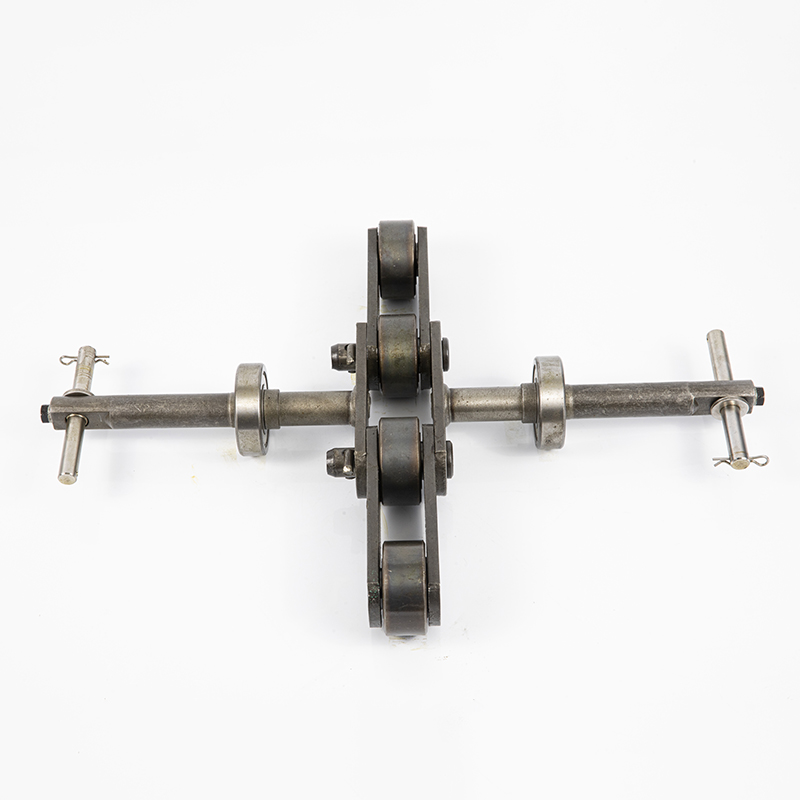

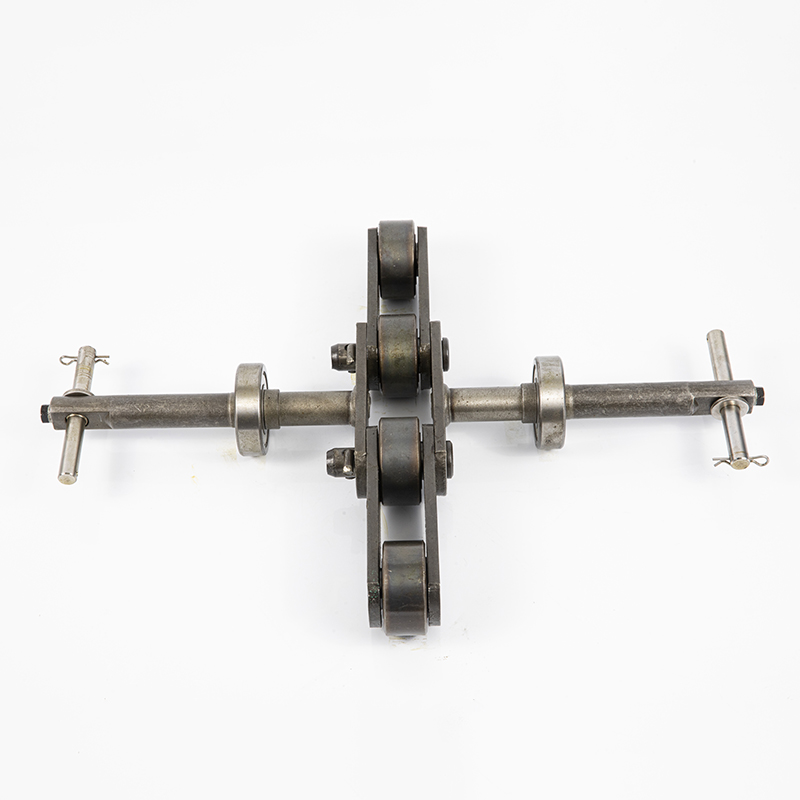

China wholesale Side Roller Chain Exporters – Double Roller Conveyor Chain For Glove Production – DEMY

China wholesale Side Roller Chain Exporters – Double Roller Conveyor Chain For Glove Production – DEMY Detail:

The types and characteristics of transmission chains are as follows:

1. The standard drive roller chain is a general drive roller chain based on JIS and ANSI specifications.

2. The plate chain is a hanging chain composed of chain plates and pins.

3. Stainless steel chain is a stainless steel chain that can be used in special environments such as medicine, water and high temperature.

4. The anti-rust chain is a chain with nickel plated on the surface.

5. The standard accessory chain is a chain with accessories attached to the standard roller chain for transmission.

6. The hollow pin chain is a chain connected by hollow pins, and accessories such as pins and cross bars can be freely attached or removed according to customer requirements.

7. Double pitch roller chain (Type A) is a chain with twice the pitch of the standard roller chain based on JIS and ANSI specifications. It is a low-speed transmission chain with an average length and a light weight. It is suitable for devices with long distances between shafts. 8. Double-pitch roller chain (C type) is twice the length of the standard roller chain based on JIS and ANSI specifications Distance of the chain. , Mainly used for low-speed transmission and handling, with standard diameter S type roller and large diameter R type roller

9. The double-pitch accessory roller chain is a chain with accessories attached to the double-pitch roller chain, which is mainly used for transport.

10. The ISO-B type roller chain is a roller chain based on ISO606-B. The products imported from the UK, France, Germany and other places use this model more.

Glove stripping machine is widely used in various glove manufacturers to provide production efficiency and product quality. It is mainly divided into: PVC glove stripping machine, nitrile glove stripping machine and latex glove stripping machine, meeting the requirements of various glove manufacturers demand.

The working process of the glove demolding machine is: the active sprocket of the synchronous force take-off mechanism meshes with the main transmission chain of the hand mold on the glove production line, and the power is transmitted to the guide rail control; the guide rail control is installed with a one-to-one correspondence with the hand mold The glove demolding mechanism can carry out the cyclic actions of longitudinal synchronous movement, lateral separation movement and mechanical claw opening and closing relative to the hand mold, thereby completing the full set of glove demolding operations; glove blowing and glove blowing respectively correspond to the initial clamping of mechanical claws To tighten the hand mold and to withdraw the gloves, the gloves can be blown on the mechanical claws or blown off from the mechanical claws, so as to realize the full automation of glove demolding.

Glove demoulding machine features: the equipment and the production line run synchronously, no motor is required, smooth operation, low noise. Gloves from fitting the hand mold, blowing and flanging, manipulator flaring, manipulator outward movement, gloves removal, etc. are completed at one time. It has the advantages of fast demoulding speed, fewer operators, low production cost, good product quality, and high yield. It can replace manual operation.

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for China wholesale Side Roller Chain Exporters – Double Roller Conveyor Chain For Glove Production – DEMY, The product will supply to all over the world, such as: Georgia, St. Petersburg, Johor, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!