China wholesale Former Holder Set For Glove Machinery – U bracket type former holder with D type disc – DEMY

China wholesale Former Holder Set For Glove Machinery – U bracket type former holder with D type disc – DEMY Detail:

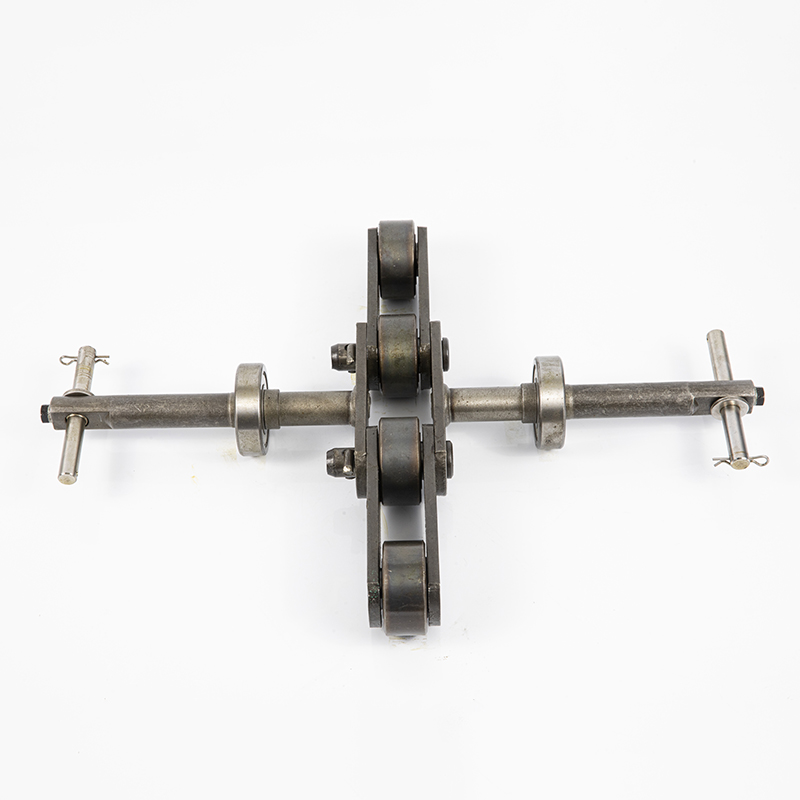

U bracket type double former holder assembly that is used in high speed latex dipping process for the production of products such as medical gloves. The former holder assembly basically consists of a U-shaped bracket , which is connected to two taper-L-shaped arms having an upright plate and a rectangular base plate . The U-shaped bracket has a base and two vertical ends and a pivotal rod. Each of the rectangular base plate of the two taper-L-shaped arms is used to hold at least on former holder. In the closed positional, the upright portion of the taper-L-shaped arms and aligned back to back with each other. In the open position the two L-shaped arms and the former holders can have an arcuate motion of up to 150°.

We specializing in producing Former Holder and Roller Conveyor Chain For Glove Production,we provide the products to customers in Malaysia.Thailand.Vietnam.Indonesia.Etc more than 15 years,we promise that:client first,cooperate in good faith and provide high quality products and perfect service with the most favrable price.letter,telphone and visit for business talking for new and former clients are welcome.

Our strengths are:Flexible manufacturing modular set-up that caters to customers from different industries.The availability of in-house production tooling supports for high production uptime. This translates into prompt delivery of parts, while maintaining optimum usage of the production resources.Experienced and professional engineers, providing services and products of the best quality in the industry.

The productivity of the dipping process depends among other things, on the speed of the chain conveyor, the centre to centre pitch of the former holders. The chain speed can vary from a few meters per minute to a high speed of over 40 meters per minute. The faster the speed, the higher is the productivity. There is a limit in which the chain speed can be increased. The maximum chain speed corresponding to the number of formers that can be conveyed per minute depends on the dipping conditions and the final properties of the finished dipped products. At fast chain speed, any slight instability of the former holder assembly can cause the formers to vibrate during the dipping process. This can cause defects in the rubbery film formed on the former resulting in dipped products having defects. Besides chain speed, increasing the number of formers in each former holder assembly (i.e. a multi-former holder assembly can hold more than one former) per cycle of dipping can also enhance the productivity. In increasing the number of former attached on each former holder assembly from one to two, will increase the productivity by 100%. It is essential that when more than one former is mounted on a former holder to increase the productivity, the formers must move steadily and independently when required. Proper mounting of the formers onto a multiple former holder assembly is therefore important.

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for China wholesale Former Holder Set For Glove Machinery – U bracket type former holder with D type disc – DEMY, The product will supply to all over the world, such as: Hyderabad, Algeria, Chicago, We have exported our products all over the world, especially the USA and European countries. Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products, please don't hesitate to contact us. We will try our best to meet your needs.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.